The global rubber market size is poised for steady growth, with an expected compound annual growth rate (CAGR) of 5.0% during the period 2025-2034. Rubber, a versatile material, plays a crucial role in industries such as automotive, aerospace, medical, defence, printing, and agriculture, among others. The market is set to benefit from rising demand for durable, flexible, and sustainable materials across these sectors. With North America, Europe, and Asia emerging as key markets, the industry is well-positioned for significant expansion over the next decade.

This article delves into the market dynamics, key drivers, challenges, emerging trends, and segmentation insights shaping the global rubber market’s future.

Understanding the Rubber Market

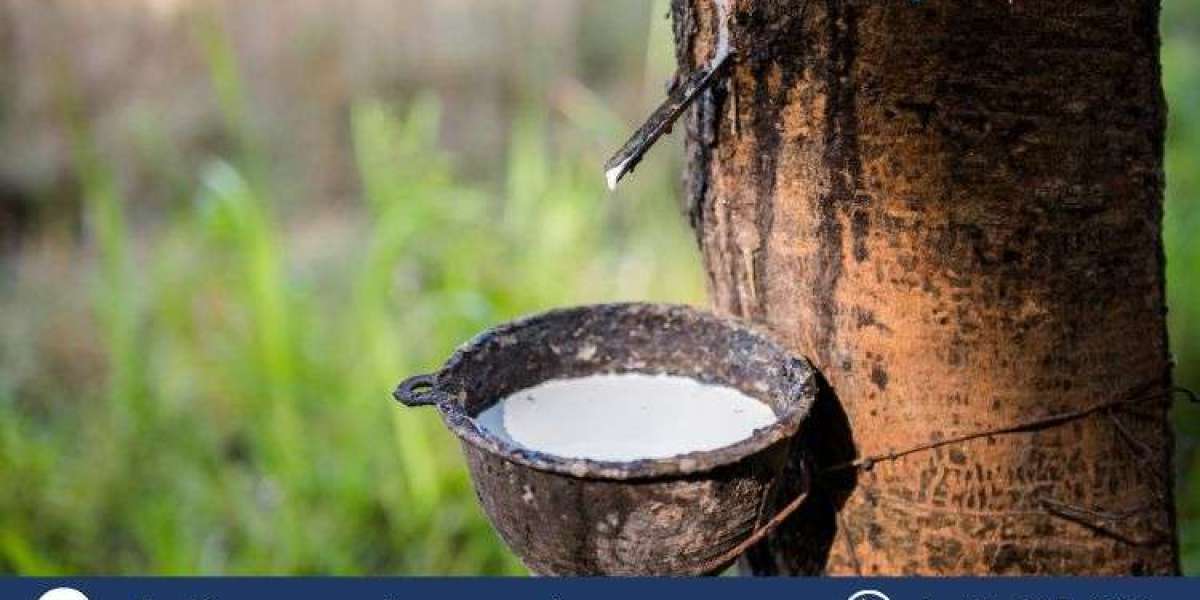

Rubber, both natural and synthetic, is a critical material for modern industries. Known for its elasticity, resilience, and durability, rubber is used in a variety of applications, ranging from vehicle tyres and seals to surgical gloves and conveyor belts. While natural rubber is harvested from rubber trees, synthetic rubber is derived from petroleum-based products and caters to applications requiring specialised properties.

As industries continue to demand innovative materials that meet performance, cost-efficiency, and sustainability requirements, the global rubber market is primed for growth.

Key Drivers of Market Growth

Booming Automotive Industry The automotive sector remains the largest consumer of rubber, accounting for a significant portion of global demand. Rubber is an essential component in tyres, belts, seals, and hoses. As the automotive industry shifts towards electric vehicles (EVs), the demand for high-performance and durable rubber components is expected to rise. Additionally, the increasing need for fuel-efficient and lightweight vehicles further drives innovation in rubber formulations.

Rising Demand in Medical Applications The medical sector’s reliance on rubber for products like surgical gloves, tubing, catheters, and seals is growing rapidly. The emphasis on hygiene and infection control, particularly after the COVID-19 pandemic, has driven demand for high-quality, latex-free synthetic rubber alternatives. These materials ensure durability and safety in critical healthcare environments.

Infrastructure Development Infrastructure projects worldwide are fueling demand for rubber-based materials in construction. Rubber is used in seals, gaskets, vibration dampeners, and other components that enhance structural integrity and longevity. With large-scale construction projects underway in Asia-Pacific, North America, and Europe, the demand for rubber in this sector is set to grow.

Agricultural Advancements The agriculture industry uses rubber in a variety of applications, including tyres for tractors and harvesters, irrigation systems, and gaskets. With increasing mechanisation and the adoption of advanced agricultural equipment, the rubber market is expected to see steady growth from this sector.

Sustainability Initiatives The rising focus on sustainability has spurred the adoption of recycled and bio-based rubbers. Manufacturers are developing eco-friendly solutions to reduce the environmental footprint of rubber production. These sustainable alternatives align with global efforts to promote green practices, contributing to market growth.

Challenges in the Rubber Market

Volatility in Raw Material Prices Fluctuations in the prices of natural rubber and petroleum-based synthetic rubber impact production costs, creating uncertainty for manufacturers. Price volatility can influence profitability, particularly for small and medium-sized enterprises.

Environmental Concerns Rubber production, particularly natural rubber, raises environmental issues, including deforestation, water pollution, and high energy consumption. Addressing these concerns requires significant investment in sustainable practices, which can pose a challenge for manufacturers.

Intense Market Competition The global rubber market is highly competitive, with numerous players vying for market share. Differentiating products through quality, cost, and sustainability is crucial for staying ahead in this competitive landscape.

Supply Chain Disruptions Global supply chain disruptions, including material shortages and logistical challenges, can affect the timely production and delivery of rubber products. These challenges have become more pronounced in the wake of the COVID-19 pandemic.

Recycling and Disposal Issues The disposal of used rubber products, particularly tyres, poses a significant environmental challenge. Developing efficient recycling technologies and waste management solutions is critical for the industry’s long-term sustainability.

Emerging Trends in the Rubber Market

Innovation in Synthetic Rubber The development of high-performance synthetic rubbers, such as silicone rubber and thermoplastic elastomers, is gaining traction. These materials offer enhanced properties like heat resistance, flexibility, and durability, catering to specialised applications in automotive, aerospace, and electronics.

Rising Adoption of Smart Materials Smart rubbers with properties like self-healing, conductivity, and temperature adaptability are becoming popular in advanced industries. These materials enhance performance and open new possibilities in electronics, wearables, and medical devices.

3D Printing with Rubber The integration of 3D printing technologies in rubber manufacturing is revolutionising production processes. This innovation allows for customised designs, faster prototyping, and reduced material waste.

Bio-Based and Recycled Rubber The focus on eco-friendly alternatives has driven the development of bio-based rubbers derived from renewable sources like dandelions and guayule. Similarly, recycled rubber is being repurposed for use in tyres, flooring, and industrial components.

Growth in Emerging Markets Regions such as Asia-Pacific, Latin America, and Africa are witnessing rapid industrialisation, creating new opportunities for rubber products. The rise of automotive manufacturing hubs and increasing infrastructure investments in these regions are driving demand.

Key Market Segments

By Type

- Natural Rubber: Widely used in tyres, industrial components, and adhesives.

- Synthetic Rubber: Preferred for specialised applications requiring enhanced properties.

By Application

- Automotive: Largest segment, driven by demand for tyres, seals, and belts.

- Medical: Growing demand for gloves, tubing, and other healthcare products.

- Industrial: Includes applications in construction, machinery, and electronics.

- Agriculture: Used in tyres and irrigation systems.

By Region

- North America: Strong demand driven by the automotive and healthcare sectors.

- Europe: Focus on sustainability and advanced manufacturing techniques.

- Asia-Pacific: Fastest-growing region due to industrialisation and infrastructure development.

- Rest of the World: Emerging markets with increasing adoption of rubber products.

Future Outlook

The global rubber market is set for steady growth, driven by rising demand from diverse industries and ongoing innovations in material science. As industries prioritise sustainability, durability, and performance, rubber manufacturers must adapt to meet evolving market demands. The integration of advanced technologies, bio-based materials, and sustainable practices will shape the market’s trajectory over the next decade.

With key markets in North America, Europe, and Asia-Pacific, and emerging opportunities in developing economies, the global rubber market is well-positioned for long-term growth. Manufacturers that focus on innovation and sustainability will lead the way in this dynamic and expanding industry.